Guangdong Jinshengxin Industrial Co., Ltd. was established in 2013 and became a member of the USB Association in 2018.

The company is a modern management enterprise specializing in the development, production, and sales of USB connectors and TYPE-C connectors, with strong technical strength and advanced production equipment. Strictly following the ISO9001:2000 quality system certification standards, we have achieved fully automated production and testing equipment, forming an integrated business system that integrates product design, mold development, hardware stamping, injection molding, assembly manufacturing, and after-sales service.

The company adheres to the business philosophy of quality first and customer first, with the aim of common development with customers. The product is widely used in various electronic consumer industries such as chargers, car chargers, electronic appliances, adapters, mobile power supplies, computer peripherals, etc. Since its launch in the market, the product has been widely recognized by customers and greatly meets market demand.

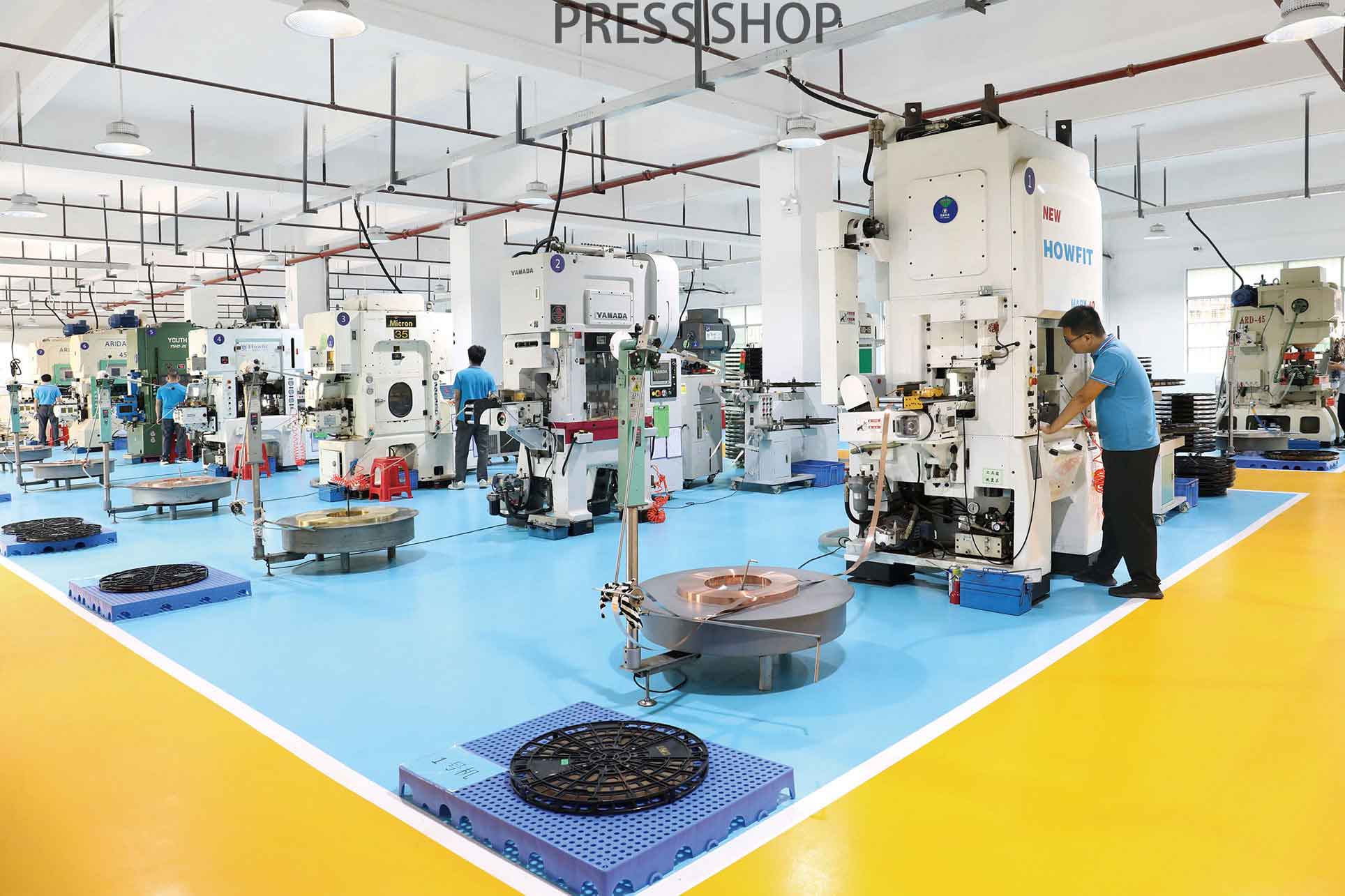

STAMPING WORKSHOP

We use a japenese imparied ganiry shaft type high-speed punch, with a mapimum punch rate of 2000 times per mirute. We specielize instamping and foming integrated high-precision teminals, hooks, and shells.

INJECTION WORKSHOP

Adopting a high-precision Japanese precision fuly elecric iniection molcding machine, the terminals and hoks are drven by efficient sanomotors and high-precision sensing cantrot, Accarding to the designed mold, molten plastic is introduced into the metal material tire fim, andthan rapidly cooled and molded to accurately control each injection process, ansuring stable product quality.

We have a professional and experienced technical p&D team with years of extensive manufacturing experience in product developmentprowiding customers with synchronous development and other technical support.

AUTOMATION WORKSHOP

Cut and assemble the outer shell and semi-finished product through an automatic machine, and integrate CcD, electrical measurement, andpackaging for splicing and assembly;, Ensure product quality and improve production afficiency.

DETECTION EOUIPMENT

We have various types of testing equipment that can simutaneously meet dozens of reliabiity requirements such as size, mechanical,electrical, environmental, ervironmental protection, and welding, providing high-guality and relable products for every customer.